Propulsion systems selection is an important part of naval ship design. These systems have always had to satisfy speed and ship-service power requirements. Nowadays, increasing fuel costs are moving such decisions towards more fuel-efficient solutions. Unlike commercial ships, naval ships operate in a variety of speeds and electric loads, making fuel consumption optimization challenging. Propulsion System choices for modern Naval Vessels depends on some criteria:

Traditional criteria

• ship speed requirements

• shock capability

• noise reduction

• infrared signature

Additional criteria

• change in operation requirements

• greater range of speed

• added mission flexibility

• longer periods away from base with smaller crews

• cleaner emissions

An emerging global macro-trend in naval engineering over the last fifteen years has been a decisive migration to ‘more electric’ propulsion due to progressively increasing electrical load demand and a focus on affordability. All-electric and hybrid electro-mechanical arrangements are routinely demonstrating merit since 1990 in the Royal Navy Type 23 ASW frigate and subsequent modern frigate programs. These include the Royal Navy Type 26, German Navy F125, Spanish Navy F110, Italian and French Navies’ FREMM, Republic of Korea Navy FFX-II frigate and Finnish Navy SQ2020 frigate programs.

Types of Propulsion Systems

Combined diesel or gas (CODOG)

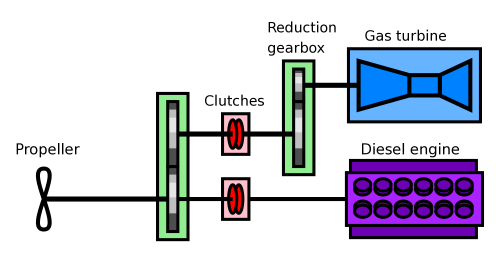

Combined diesel or gas (CODOG) is a type of propulsion system for ships that need a maximum speed that is considerably faster than their cruise speed, particularly warships like modern frigates or corvettes.

For every propeller shaft there is one diesel engine for cruising speed and one geared gas turbine for high-speed dashes. Both are connected to the shaft with clutches; only one system is driving the ship, in contrast to CODAG systems that can use the combined power output of both. The advantage of CODOG is a simpler gearing compared to CODAG, but it needs either more powerful or additional gas turbines to achieve the same maximum power output. The disadvantage of CODOG is that the fuel consumption at high speed is poor compared to CODAG.

Combined diesel and gas (CODAG)

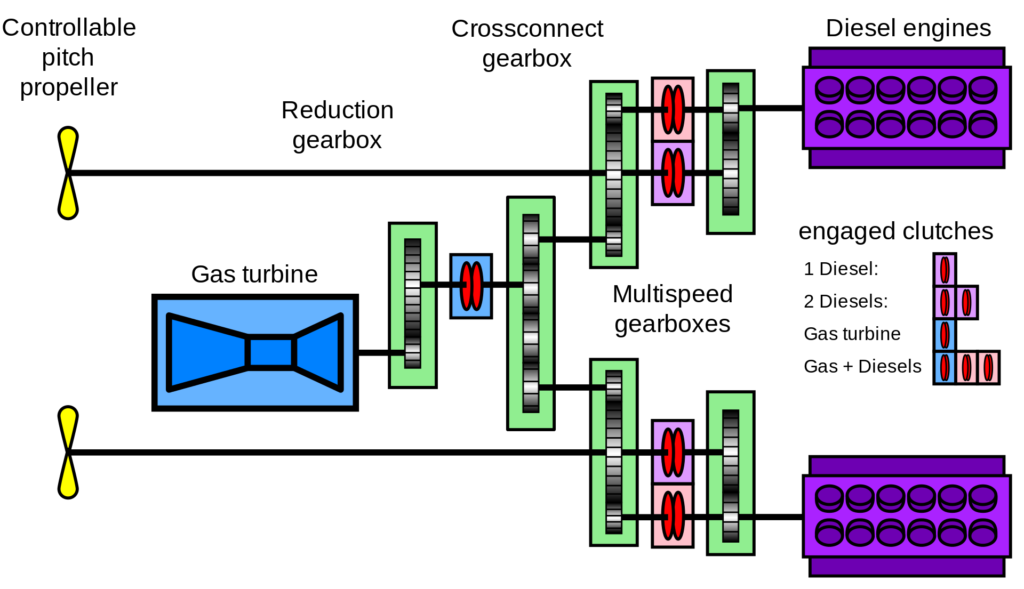

Combined diesel and gas (CODAG) is a type of propulsion system for ships that need a maximum speed that is considerably faster than their cruise speed, particularly warships like modern frigates or corvettes.

Pioneered by Germany with the Köln-class frigate, a CODAG system consists of diesel engines for cruising and gas turbines that can be switched on for high-speed transits. In most cases, the difference of power output from diesel engines alone to diesel and turbine power combined is too large for controllable-pitch propellers to limit the rotations so that the diesels cannot continue to operate without changing the gear ratios of their transmissions. Because of that, special multi-speed gearboxes are needed. This contrasts to combined diesel or gas (CODOG) systems, which couple the diesels with a simple, fixed ratio gearbox to the shaft, but disengage the diesel engines when the turbine is powered up.

For an example the new CODAG-propelled Fridtjof Nansen-class frigates of the Royal Norwegian Navy, the gear ratio for the diesel engine is changed from about 1:7.7 (engine:propeller) for diesel-only to 1:5.3 when in diesel-and-turbine mode. Some ships even have three different gear ratios for the diesel engines — one each for single-diesel and double-diesel cruises, and the third when the gas turbine is engaged.

Such a propulsion system has a smaller footprint than a diesel-only power plant with the same maximal power output, since smaller engines can be used and the gas turbine and gearbox don’t need that much additional space. Still, it retains the high fuel efficiency of diesel engines when cruising, allowing greater range and lower fuel costs than with gas turbines alone. On the other hand, a more complex, heavy, and troublesome gearing is needed.

Typical cruising speed of CODAG warships on diesel-power is 20 kn (37 km/h; 23 mph) and typical maximal speed with switched on turbine is 30 kn (56 km/h; 35 mph).

Combined diesel-electric and diesel (CODLAD )

CODLAD (COmbined Diesel-eLectric And Diesel) is a naval propulsion system in which an electric motor and a diesel engine act on a single propeller. The transmission system takes care of making one or both motors act on the propeller shaft.

The CODLAD propulsion system is based on the use of electric motors directly connected to the axes (generally two) of the propellers. The electric motors are powered by diesel generators and to have higher speeds, as happens in CODAD propulsion systems, the higher power diesel engine is inserted which is disconnected from the transmission system to return to cruising speed.

This system that uses diesel engines for both propulsion and for the production of electricity for on-board services significantly reduces costs, as the number of diesel engines for the various ship services decreases and the electric motors need less maintenance. Furthermore, since electric motors can work more effectively in a larger number of revolutions, and being directly connected to the propeller axis, the transmission systems for coupling and decoupling the diesel-electric systems with the diesel engines used to have higher speeds.

The CODLAD system has been adopted in the new Vulcano-class logistic support ship under construction for the Italian Navy.

Combined diesel-electric and gas (CODLAG)

Combined diesel-electric and gas (CODLAG) is a modification of the combined diesel and gas propulsion system for ships. A variant, called the combined diesel-electric or gas (CODLOG) system, contains the same basic elements but will not allow simultaneous use of the alternative drive sources.

A CODLAG system employs electric motors which are connected to the propeller shafts (usually 2). The motors are powered by diesel generators. For higher speeds, a gas turbine powers the shafts via a cross-connecting gearbox; for cruise speed, the drive train of the turbine is disengaged with clutches.

This arrangement combines the diesel engines used for propulsion and for electric power generation, greatly reducing service cost, since it reduces the number of different diesel engines and electric motors, requiring considerably less maintenance. Also, electric motors work efficiently over a wide range of revolutions and can be connected directly to the propeller shaft so that simpler gearboxes can be used to combine the mechanical output of turbine and diesel-electric systems.

Another advantage of the diesel-electric transmission is that without the need of a mechanical connection, the diesel generators can be decoupled acoustically from the hull of the ship, making it less noisy. This has been used extensively by military submarines but surface naval vessels like anti-submarine vessels will benefit as well.

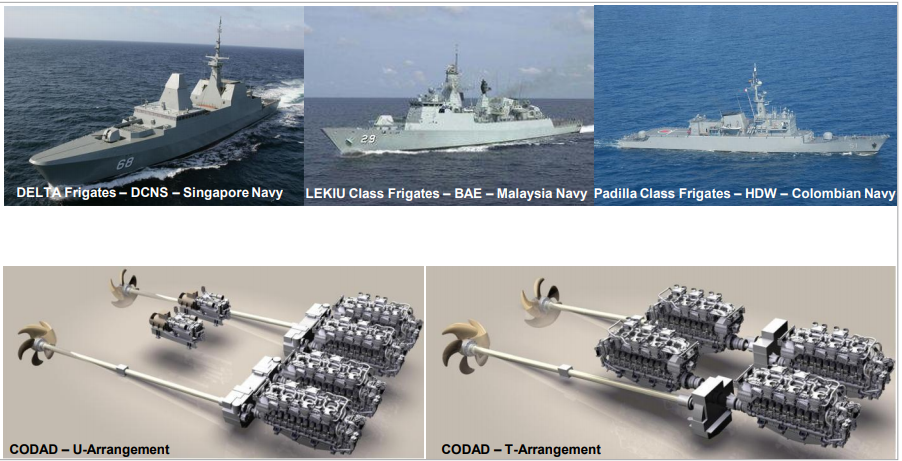

Combined diesel and diesel (CODAD)

Combined diesel and diesel (CODAD) is a propulsion system for ships using two diesel engines to power a single propeller shaft. A gearbox and clutches enable either of the engines or both of them together to drive the shaft. Two advantages over simply using a single, larger diesel engine of the same total power output are that (1) diesel engines have somewhat better specific fuel consumption at 75% to 85% max output than they do at only 50% output, and (2) there is a weight and size advantage to using two higher-speed engines compared to a single lower-speed engine, even with the slightly larger gearbox system.

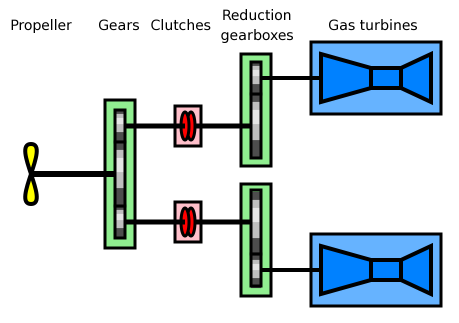

Combined gas or gas

Combined gas or gas (COGOG) is a propulsion system for ships using gas turbine engines. A high-efficiency, low output turbine is used for cruising speeds with a high output turbine being used for high-speed operations. A clutch allows either turbine to be selected, but there is no gearbox to allow the operation of both turbines at once. This has the advantage of not requiring heavy, expensive, and potentially unreliable gearboxes.

The reason that a smaller turbine is used for cruising is that a small turbine running at 100% power is more fuel efficient than a bigger turbine running at 50% power.

The system is currently used in the 3 ships of the Russian Navy’s Slava-class cruisers, the Japanese Maritime Self-Defense Force’s Hatsuyuki-class destroyers, and the Dutch Navy Kortenaer-class frigates (on which the Greek Navy Elli-class frigates are based).

Combined gas and gas

Combined gas turbine and gas turbine (COGAG) is a type of propulsion system for ships using two gas turbines connected to a single propeller shaft. A gearbox and clutches allow either of the turbines to drive the shaft or both of them combined.

Using one or two gas turbines has the advantage of having two different power settings. Since the fuel efficiency of a gas turbine is best near its maximum power level, a small gas turbine running at its full power is more efficient compared to a twice as powerful turbine running at half power, allowing more-economical transit at cruise speeds.

Compared to Combined diesel and gas (CODAG) or Combined diesel or gas (CODOG), COGAG systems have a smaller footprint but a much lower fuel efficiency at cruise speed and for CODAG systems it is also somewhat lower for high-speed dashes.

Combined nuclear and steam propulsion

Combined nuclear and steam propulsion system (CONAS) is used on the Kirov-class guided missile cruisers.

Complementary to the nuclear component, there are two conventional boilers installed as a backup in case of reactor failure. Both components can drive two geared steam turbines, generating 120,000 hp (89 MW), at two prop shafts

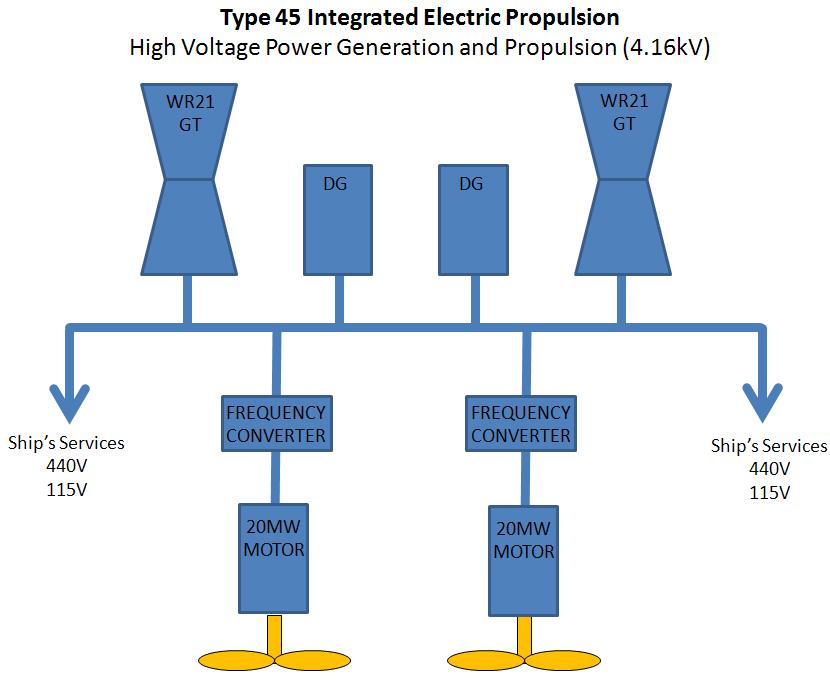

Integrated electric propulsion

Integrated electric propulsion (IEP) or full electric propulsion (FEP) or integrated full electric propulsion (IFEP) is an arrangement of marine propulsion systems such that gas turbines or diesel generators or both generate three-phase electricity which is then used to power electric motors turning either propellers or waterjet impellors. It is a modification of the combined diesel-electric and gas propulsion system for ships which eliminates the need for clutches and reduces or eliminates the need for gearboxes by using electrical transmission rather than the mechanical transmission of energy, so it is a series hybrid electric propulsion, instead of parallel.